Types of vacuum pumps used in industries - 2023

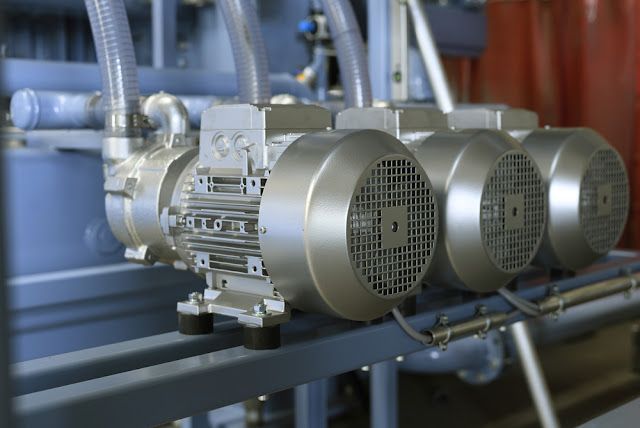

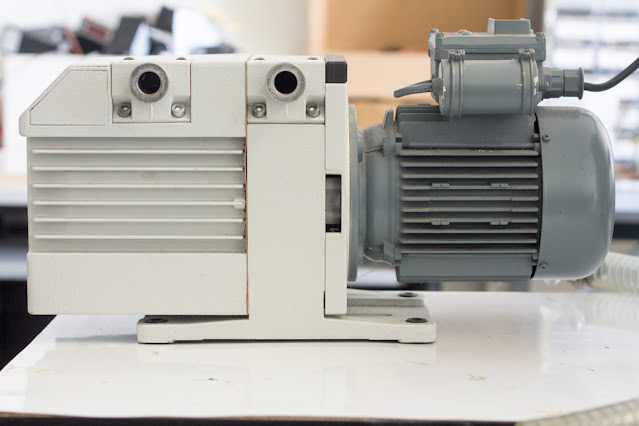

There are several different types of vacuum pumps, each better suited to certain tasks than others. The most common vacuum pumps are rotary vane pumps, piston pumps, diaphragm pumps, and screw pumps.

This article will look at the different types of vacuum pumps and their applications in various industries.

Different types of vacuum pumps:

Vacuum pumps play an important role in many industries, from manufacturing and food processing to pharmaceuticals and medical applications. Many different types of vacuum pumps are available on the market, each with its unique set of features and applications.

Some of the most common types of vacuum pumps used in industries include:

- Rotary vane pumps: These are commonly used in manufacturing applications and are known for their durability and leak-free operation.

- Diaphragm pumps: These pumps are commonly used in food processing and pharmaceutical applications because they can handle liquids and gases without contamination.

- Piston pumps: These are often used in medical applications because they can create a high vacuum level.

- Screw pumps: These are commonly used in oil and gas applications because they can handle large volumes of fluids.

Which industries use vacuum pumps?

Vacuum pumps are used in various industries to create a vacuum environment. They are used in the semiconductor industry to create the vacuum environment necessary for manufacturing semiconductor devices. They are also used in the medical industry for various applications, including blood transfusions and MRI machines. Additionally, vacuum pumps are used in the food and beverage industry, as well as the pharmaceutical industry.

Why are vacuum pumps necessary for industries?

Vacuum pumps play an important role in many industries, from food and beverage to pharmaceuticals. They remove air from a sealed container to create a vacuum. This vacuum can then be used for various purposes, such as:

- To fill a container with a gas

- To remove fluid from a container

- To prevent contamination

- To create a vacuum for welding or other industrial processes

Vacuum pumps are an essential part of many industries and can be used for various purposes. Investing in a quality vacuum pump is a great place to start if you're looking for a way to improve your operations.

How do vacuum pumps work in industries?

Vacuum pumps are essential equipment in many industries, from chemical and pharmaceutical manufacturing to food processing. But how do they work?

Vacuum pumps work by creating a vacuum, or an area of low pressure, inside a sealed container. This low pressure allows the pump to suck air or other gases out of the container. As the amount of air or gas in the container decreases, the vacuum pump can create an even greater vacuum.

This process can be used to remove impurities from a gas or to create a space where a reaction can take place. Vacuum pumps are also used in other applications, such as pumps that remove water from swimming pools.

Advantages and disadvantages of using vacuum pumps:

A vacuum pump is a device that uses air pressure to create a vacuum. Vacuum pumps are used in various industries, from manufacturing to medicine. They have several advantages and disadvantages that should be considered before using one.

Advantages:

1. Vacuum pumps can create a vacuum in a process chamber without needing an evacuation port.

2. Vacuum pumps can be used to pump out process gases from a chamber.

3. Vacuum pumps can create a vacuum in a container.

Disadvantages:

1. Vacuum pumps can be noisy.

2. Vacuum pumps can be expensive to purchase.

3. Vacuum pumps require regular maintenance.

So, many different types of vacuum pumps are used in industries, each with its advantages and disadvantages. Some of the most common vacuum pumps are oil-sealed rotary vane pumps, dry scroll pumps, and rotary screw pumps. To learn more about the different types of vacuum pumps and find the one that best fits your needs, check out our website.

Comments

Post a Comment