The Vacuum Pump – How It Works and What To Look For

To retail or buy a vacuum pump, you’ll need to decide which type makes the most sense for your situation. A rotary pump generally produces the highest vacuum while a linear pump produces the lowest vacuum. The highest vacuum is created by replacing the air inside the chamber of your pump with a high-speed fan. More specifically, these pumps are popular for drawing blood into a syringe. This feature allows the volume of blood to be replaced much faster than other pumps which have slower rotational speeds (like the household dust collectors mentioned previously). Since low vacuum is important for removing blood from a vein, a pump with a high rotation speed is usually required to accomplish this. However, in vehicles (such as ambulances) or in medical chambers, a high-pitched, screaming fan may actually create more vacuum. Because of this reason, a supplemental fan is used to create a vacuum at higher speeds in order to achieve the same result as a faster pump.

What this accomplishes is that there isn’t as much scar tissue to short circuit and there are more open circuits available for the blood to move through. This can be advantageous in instances where faster pumps would not suffice. The rotary pump may work at higher speeds but requires extra maintenance. Because of the slow speed of rotary pumps, this can cause it to the take longer to complete a phase one draw (i.e. drawing blood). For example, if the fan is set to run at 10 rpm, it will take approximately 4 seconds to fill the container with blood compared to a linear pump which can go up to 25 rpm. A vacuum pump works through a series of pumping strokes that burp or draw air into a chamber. The air is expelled through a series of ports that are arranged horizontally. The electronic signal used to control the speed of the pump also instructs where to place each port on the pump to create a vacuum inside your chamber. The principle of a pump also varies depending on how powerful your motor or fan is. For example, on a linear pump, the main circuit runs all the way up to about 100,000 rpm. So in order to create a vacuum, you’ve typically matched the impeller to a speed sensor and then activate the fan to spin at a high speed. On a rotary vacuum pump, the motor is used to spin the exhaust air to create a vacuum. This speeds the pump up without damaging the impeller, allowing more air to be pulled in without fear of damaging it.

How Do You Choose the Right Vacuum Pump For Your Needs

The first thing to consider when buying any vacuum pump is how big the chamber needs to be. A chamber is the space inside a device where the vacuum is created. There are different types and sizes of chambers so please check with your pump manufacturer to find out what size will work best in your enclosure. If you want to focus on measuring the vacuum created in a small space, a micrometaller vacuum pump or a restricted air pump might be better suited for you. For larger chambers, a larger diameter pump may be needed. We encourage you to go to the appropriate product page for a vacuum pump that has the proper vacuum for your enclosure. All vacuum pumps contain some sort of permanent magnet.

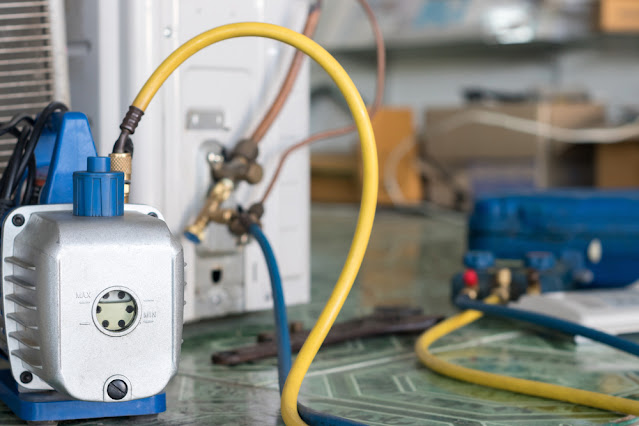

These magnets hold the chamber inside the pump and rotate during operation. Each time the magnet completes one cycle around the chamber, it releases a small amount of pressure which is drawn into the chamber through a tube connecting the two sides. Does it seem complicated? It isn’t! This might sound a bit complicated, but it’s really not all that different from using a regular air pump. A couple of pictures will help here. Figure 1 (Left) is a view from the inside of a typical air pump. You can see that the pump has a pump body at each end (blue part) and a fan or compressor at the other end (red part). You’re basically looking at how it creates and removes air. Figure 2 (Right) is a view from the inside of a vacuum pump. Here you’ll see the pump body (green part) and the fan or compressor.

Everything you need to know about the internals of a vacuum pump is contained in the two (2) drawings here. One (left) is of an inductive pump. This pump uses the magnetic field created by the permanent magnet that coils around an iron core (cathode) to create the vacuum. The other (right) is of a rotary pump. This pump relies on a tiny spinning impeller to create the vacuum. These two types of pumps essentially work the same except that inductive pumps need a conductor in the middle to create the magnetic field and that needs to be charged. When selecting a pump, consult the directions that came with your vacuum pump. These will tell you what type of impeller to buy. We suggest that you stick with pump types that use a rotary impeller (figure 2) as they tend to be the most robust and last the longest.

The vacuum pump is an essential tool for many industrial applications

For people looking to create their own vacuum pumps, it is possible to find two of the most popular options. The cheaper version is called a power vacuum sender. It consists of a rotary pump connected to a high-efficiency particulate air (HEPA) filter. The HEPA filter captures small particles of dust, dirt, and pollen and consists of a string of fine mesh tightly packed together. This filter has a specific size, which is expressed in microns. The output of the pump is often referred to as a particle air purifier (PA). This type of vacuum pump has several advantages over a standard pump such as the following. Much like how a stove uses heat to create a vacuum in a dishwasher, the same principle is used to create a vacuum in a vacuum pump. The heat produced by the rotary pump in the vacuum pump is then directed into a diaphragm called the diaphragm pulley, causing it to vibrate. This vibration drives the air out of the chamber. A source of air now remains in the chamber and the vacuum pump continues to create a vacuum. The opposite setup on the other hand, closes the diaphragm with a constant air intake which is only used to maintain the vacuum.

This type of vacuum pump uses no DC power at all. Instead, it is powered by the AC current which is provided by a battery. It’s important to mention that both pump types require power to run. Because vacuum pumps use DC power to produce their vacuum, they are often grouped under the heading of forced air systems. The purpose of a forced air system is to provide for the reuse of exhausted vacuum by simultaneously extracting air and replacing exhausted air with fresh air. This is accomplished using an air compressor. An air compressor is a device that is used to extract the air from the vacuum chamber. There are two common types of compressor: progressive and rotary. An air compressor is used to suck air into the chamber. The terminal (apex) of a vacuum pump is a ball-shaped device that receives the air impeller by means of a shaft: In the progressive compressor, there are two rotating parts which are called axial and eccentric. The axial compressor, like the power vacuum sender, has a smaller, narrower chamber, leaving more space within the chamber for the air to circulate. In contrast, the axial compressor has a larger chamber and is larger in volume. The gearing can adapt the size of the chamber depending on the capacity (watt rating) of the motor used.

Comments

Post a Comment